Testing Systems

🧪 Industrial Testing Systems Tailored to Your Needs

At Tork Mekatronik, we specialize in designing and manufacturing high-precision test systems that ensure product quality, safety, and compliance. Whether for leak detection, functional verification, or data-driven analysis, our solutions are trusted across industries including automotive, electronics, and white goods.

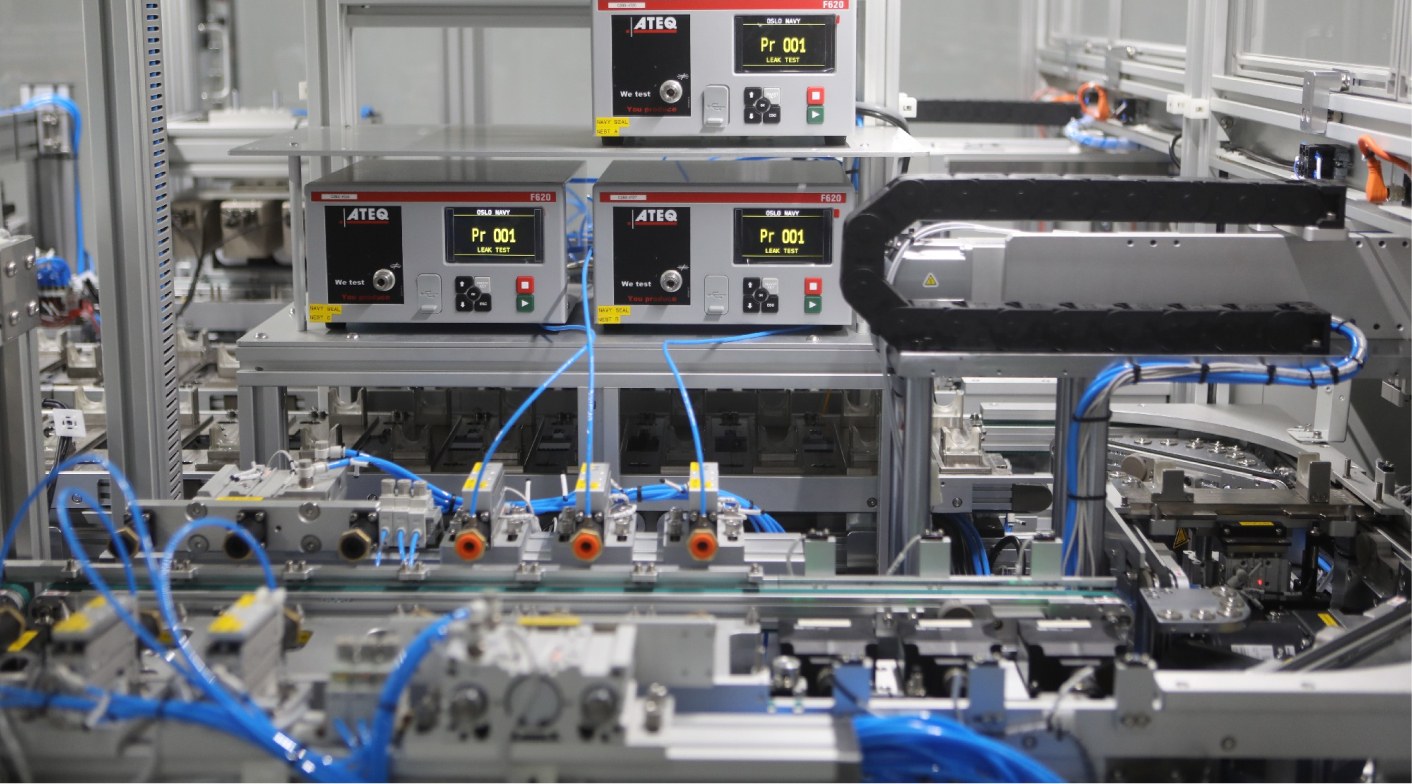

🔍 Leakage Testing

Detects air or fluid leaks in sealed components using pressure decay and flow measurement systems.

✅ Our Expertise in ATEQ Integration

We are an official ATEQ system integrator, providing fully customized leak test stations, automation lines, and PLC-integrated solutions using ATEQ’s world-renowned instruments. Whether your application requires compact bench-top setups or fully automated conveyor lines, we integrate ATEQ technology for maximum precision and speed.

👉 Explore our ATEQ Integration Services

⚡ Electrical Conductivity Testing

Evaluates the ability of materials and components to conduct electric current reliably, ensuring safety and performance in electronic systems.

🔌 Resistance Testing

Measures resistance in circuits and components to detect faults, verify design specifications, and maintain quality standards.

🔩 Torque Testing

Validates the mechanical strength of fasteners, screw joints, and assemblies by accurately measuring tightening force and breakaway torque. Ideal for quality-critical connections.

⚙️ Functional Testing

Simulates real-world operating conditions to assess the mechanical and electrical functionality of machines, devices, or components.

👉 See our Electrical & Functional Testing Solutions

👁️ Visual Inspections

Automated vision systems enhanced with AI detect surface anomalies, misalignments, and missing components — ensuring visual integrity in high-speed production lines.

📏 Pressure Testing

Confirms the pressure resistance of components and assemblies under both static and dynamic conditions — vital for pressurized systems.

🔥 Thermal Testing

Analyzes thermal behavior and resistance to heat in critical conditions, ensuring components perform under varying temperature environments.

🧠 Advanced Data & Smart Integration

- 💾 SQL Database Logging: Every test result is securely stored in SQL databases for traceability and deep analysis.

- 📊 Trend Analysis: Identify long-term behavior and production patterns to improve consistency and efficiency.

- 🤖 Machine Learning Integration: Historical test data can be used for predictive optimization, quality control, and adaptive process improvements.

🚀 Why Choose Tork Mekatronik?

- 🛠️ Tailor-made testing stations for every industry

- 🌐 Turnkey integration including mechanical, electrical, and pneumatic systems

- 📡 Real-time monitoring and data acquisition systems

- 🔄 Long-term support, upgrades, and remote services

📩 Let’s Build Your Testing Solution

From a single test bench to a fully automated multi-station system, Tork Mekatronik delivers reliable, smart, and scalable test equipment to elevate your manufacturing quality and efficiency.