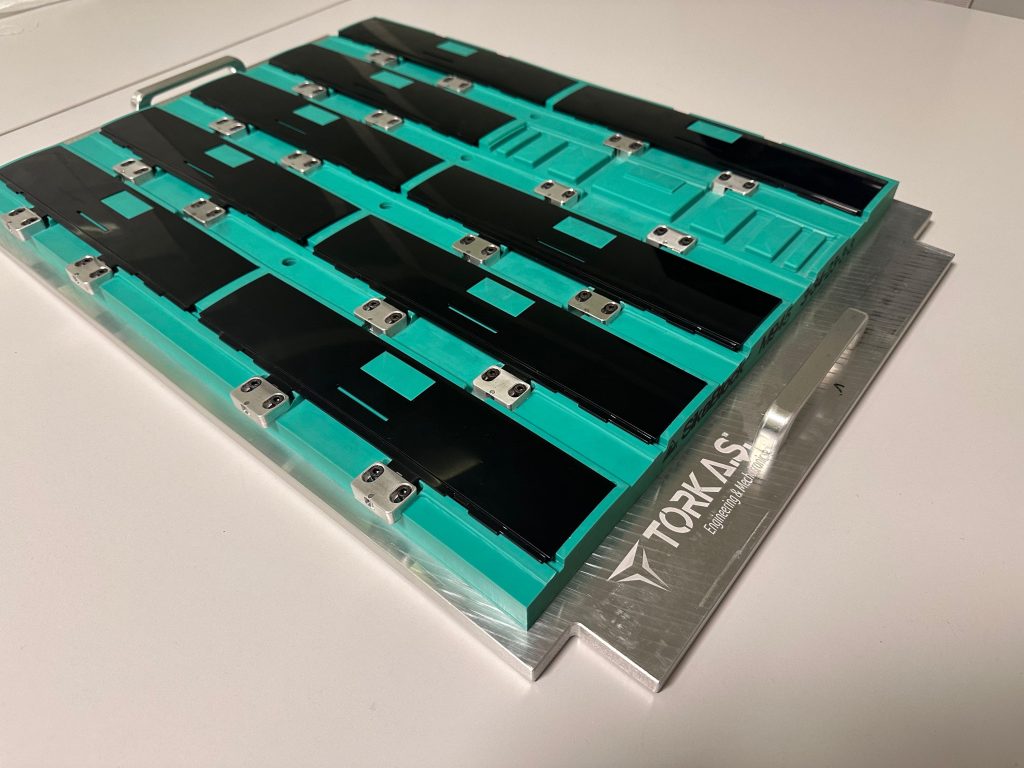

Jig & Fixture Manufacturing

At Tork Mekatronik, we deliver tailor-made fixture and jig solutions designed to accelerate your production, ensure flawless quality, and optimize your workflow. Whether you need precise measurement fixtures or production line assembly aids, every design is customized to your unique requirements.

🔍 What Are Fixtures and Why Are They Essential?

Fixtures are vital tools that accurately position and securely hold parts during manufacturing, enabling consistent and repeatable processes.

- Measurement Fixtures: Guarantee precise dimensional inspections, reducing errors and scrap rates.

- Assembly Fixtures: Ensure parts remain correctly positioned on production lines, enhancing speed and quality.

⚙️ Boost Efficiency with Jigs

Jigs serve to guide and position parts during machining or assembly operations.

- Provide consistent, repeatable positioning to minimize defects.

- Improve throughput and product consistency, especially in mass production.

🛠️ Material Selection — Engineered for Performance

| Material | Key Properties | Typical Applications | Advantages | Limitations |

|---|---|---|---|---|

| POM | High durability, excellent wear resistance | Precision fixtures, sliding or rotating parts | Long service life, dimensional stability | Moderate chemical resistance |

| Delrin® | Low friction, high chemical resistance | Moving parts, bearing surfaces | Smooth operation, resistant to solvents | Less impact resistant than POM |

| SIKABLOCK® | High-performance composite with excellent strength | Heavy-duty fixtures, harsh environments | Exceptional mechanical strength | Higher cost |

| DURAWOOD® | Plastic low-foam extrusion molded product | Kitting boxes, trolleys, logistic furniture | Lightweight, ergonomic, easy to machine and weld, protects parts | Limited load-bearing capacity |

| Aluminum | Lightweight, strong, corrosion-resistant | Structural fixtures, machine components | High strength-to-weight ratio | Can be prone to scratching |

| Teflon (PTFE) | High heat resistance, very low friction | Special applications requiring chemical/thermal stability | Excellent chemical resistance, low friction surface | Lower mechanical strength |

🎯 Why Choose Tork Mekatronik for Fixture and Jig Manufacturing?

- Custom Design: Each project is uniquely engineered to meet your exact needs.

- Precision Manufacturing: Adhering strictly to your quality standards.

- Durability: Use of premium materials for long-lasting performance.

- Increased Efficiency: Enhancing production speed and accuracy while reducing costs.

- Expert Support: End-to-end engineering assistance from design to installation.

🚀 Typical Application Industries

- Automotive

- White Goods

- Electronics & Electrical

- Aerospace

- Medical Devices

- And many more

📞 Contact Us Today!

Ready to revolutionize your production with customized fixtures and jigs?

Tork Mekatronik is your trusted partner for innovation, quality, and performance.

Boost your competitive edge — get in touch with us now!

Tork Mekatronik – Empowering Your Production with Precision and Reliability!